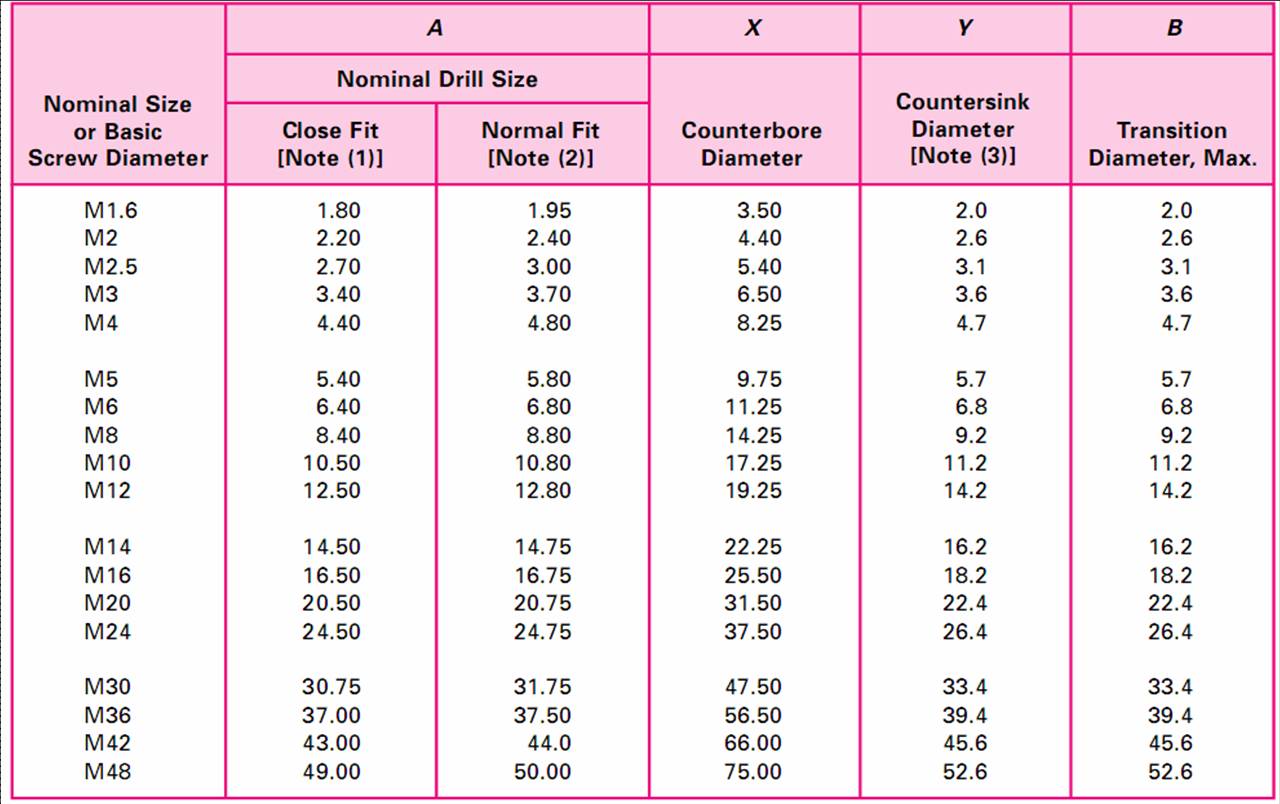

DRILL AND COUNTERBORE SIZES FOR METRIC SOCKET HEAD CAP SCREWS

Thread forms and designations have been the subject of

many long and arduous battles through the years.

Standardization in the inch series has come through

many channels, but the present unified thread form could

be considered to be the standard for many threaded

products, particularly high strength ones such as socket

head cap screws, etc. In common usage in U.S.A.,

Canada and United Kingdom are the Unified National

Radius Coarse series, designated UNRC, Unified National

Radius Fine series, designated UNRF, and several special

series of various types, designated UNS. This thread,

UNRC or UNRF, is designated by specifying the diameter

and threads per inch along with the suffix indicating the

thread series, such as 1/4 - 28 UNRF. For threads in Metric

units, a similar approach is used, but with some slight

variations. A diameter and pitch are used to designate

the series, as in the Inch system, with modifications as

follows: For coarse threads, only the prefix M and the

diameter are necessary, but for fine threads, the pitch is

shown as a suffix. For example, M16 is a coarse thread

designation representing a diameter of 16 mm with a

pitch of 2 mm understood. A similar fine thread part

would be M16 x 1.5 or 16 mm diameter with a pitch of

1.5 mm.Note 1

Close Fit: Normally limited to holes for those lengths of screws threaded to the head in assemblies in which: (1) only one screw is used; or (2) two or more screws are used and the mating holes are produced at assembly or by matched and coordinated tooling.

Note 2

Normal Fit: Intended for: (1) screws of relatively long length; or (2) assemblies that involve two or more screws and where the mating holes are produced by conventional tolerancing methods. It provides for the maximum allowable eccentricty of the longest standard screws and for certain deviations in the parts being fastened, such as deviations in hole straightness; angularity between the axis of the tapped hole and that of the hole for the shank; differneces in center distances of the mating holes and other deviations.

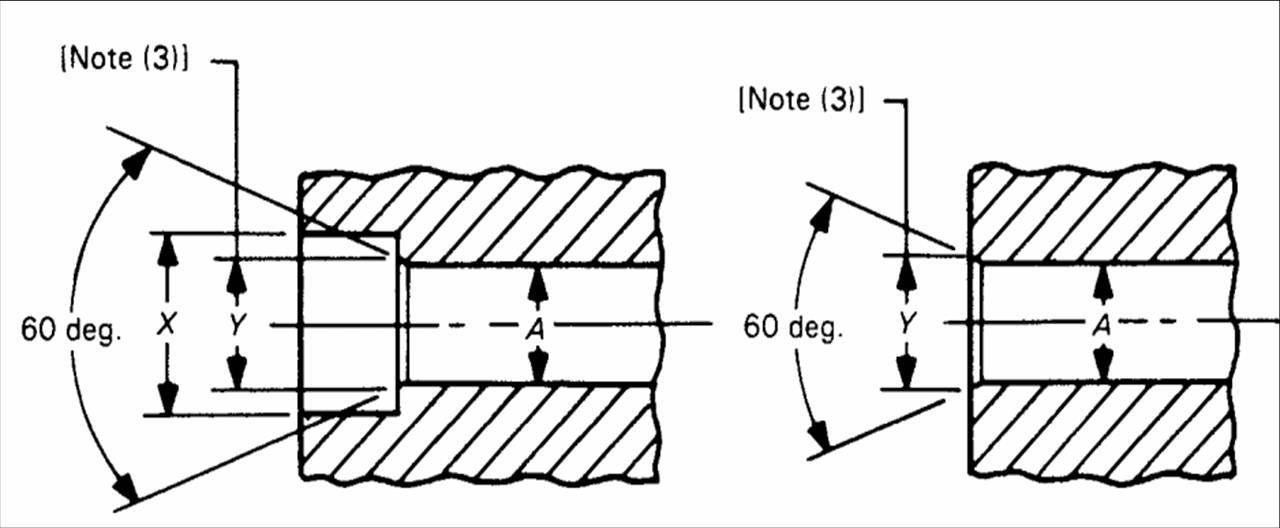

Note 3

Chamfering: It is considered good practice to chamfer or break the edges of holes that are smaller than "B" max mum in parts in which hardness approaches, equals or exceeds the screw hardness. If holes are not chamfered, the heads may not seat properly or the sharp edges may deform the fillets on the screws, making them susceptible to fatigue in applications that involve dynamic loading. The chamfers, however, should not be larger than needed to ensure that the heads seat properly or that the fillet on the screw is not deformed. Normally, the chamfers do not need to exceed "B" maximum. Chamfe exceeding these values reduce the effective bearing area and introduce the possibility of indentation when the parts fastened are softer than screws, or the possiblity of brinnelling of the heads of the screws when the parts are harder than the screws.